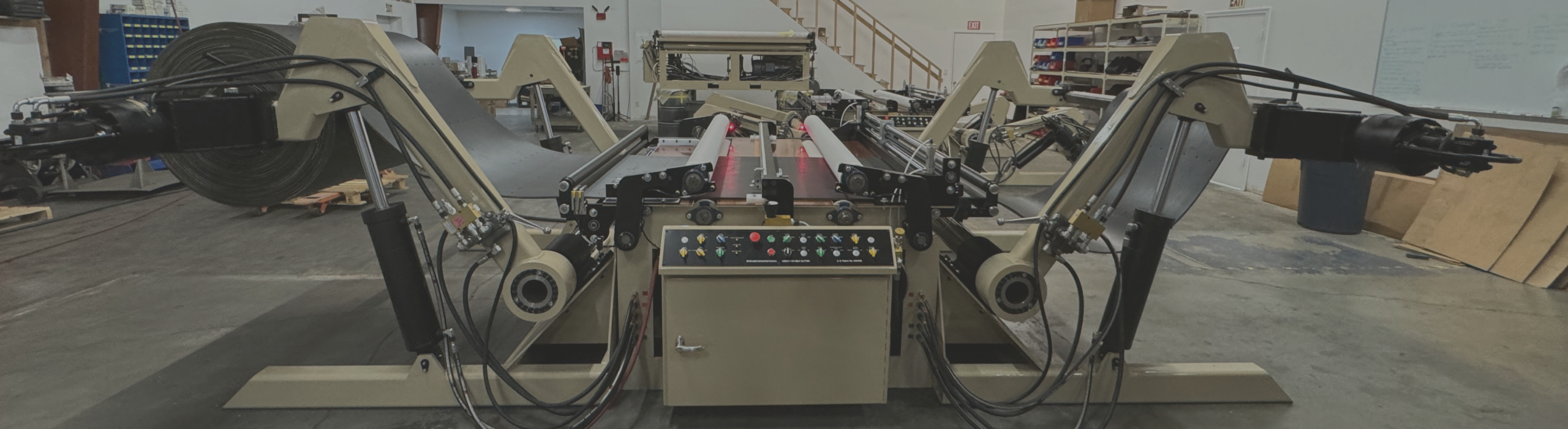

Belt Winder

Premium Belt Winder

| Standard Features include: |

|

For winding up the belt, the Spencer line of Belt Winders is capable of handling the belt once it’s been slit and cut. We offer fixed shop, mobile shop, and gas-powered mobile field units. Winder models available range from a 5k 48″ model to a 30k 96″ model.

Our patented features, like the quick-release drive chuck and swing-out gearboxes, make it the easiest to operate and quickest to change the belt. Field units can be built with separate skids for the controls and power unit. They come with tie-down eyes on the frame skid, as well as fork tubes and lifting eyes to move the belt winder. An optional manual counter can be added near the idler roll. Our standard winder is electric/hydraulic. The hydraulic drive system consists of either one or two core bar drive motor/gearbox assemblies. We use a pressure-compensated piston pump with complete hydraulic direction/speed controls, along with a self-contained hydraulic system